Heavy-duty CNC roll lathes are mainly used for roll hole processing. They can also turn the outer circle and roll neck of rolls, and can turn parts similar to rolls. It is suitable for cutting various materials such as cast steel, forged steel, alloy steel, chilled cast iron, ductile iron, tungsten carbide roll rings, etc., achieving the effect of turning instead of grinding, reducing costs and improving efficiency.

Overall layout and composition of the machine:

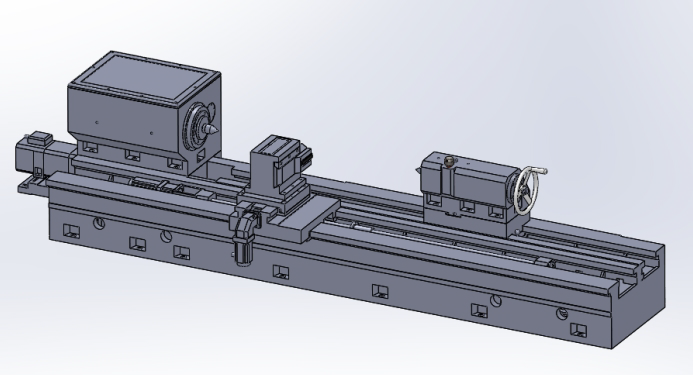

This machine adopts the layout of HT300 castings and horizontal lathes. It consists of functional components such as the bed, headstock, tailstock, slide, protective device, and electronic control system, as shown in the figure below:

The bed is the basic part of the machine tool. It has a headstock box on the upper left part, and four rectangular guide rails on the bed. After the bed blank is cast, it is tempered once, and after the rough processing, it is tempered again, and after the semi-finishing processing, a vibration aging is performed before the last finishing to eliminate internal stress, so the bed deformation is small and the wear resistance is good.

The spindle transmission mechanism uses a servo motor to connect the gear end pulley through a V-belt pulley and then drive the spindle transmission, so that the spindle can obtain a stepless speed regulation of 1 to 200r/min. The spindle servo motor and the transmission mechanism are connected by a V-belt, and the power is transmitted to the faceplate through the mechanism speed gear, so that the faceplate reaches the specified torque. The spindle part consists of a faceplate, a spindle bearing, a spindle, etc.

The tailstock is composed of an upper body and a lower body. The upper body has a tailstock spindle, a sleeve and a spindle centerline adjustment mechanism. The lower body is equipped with a reduction motor for moving the tailstock and a tailstock positioning device. The tailstock is installed on the two guide rails of the bed and can move longitudinally along the bed rails.

The large slide of the machine tool is made of high-strength and low-stress alloy cast iron (HT300). After the blank is cast, it is tempered once, and after the rough machining is completed, it is tempered again. After the semi-finishing is completed, a vibration aging is performed before the last finishing. The structural design ensures thermal symmetry and thermal stability, and has high rigidity and strength.

The lathe tool holder can be a frame type tool holder or a 4-station vertical electric tool holder (with built-in motor) according to the customer's selection. The tool holder of the electric tool holder can be interchanged at various positions of the tool disc and can be rotated left and right to change the tool at will.

Technical parameter:

| Maximum machining diameter | Φ650mm |

| Workpiece length | 3000mm |

| Spindle speed | 1rpm~200rpm |

| Spindle center height | 1105mm |

| Spindle motor power | 30KW |

| Z-axis motor power | 5.2KW |

| X-axis motor power | 3.0KW |

| Z-axis feed speed range | 1~3000mm/min |

| X-axis feed speed range | 1~3000mm/min |

| Distance from spindle center to guide rail | 475mm |

| Distance from spindle center to tailstock center | 3000mm |

| Distance from spindle center to carriage | 275mm |

| Diameter of spindle end chuck | Φ650 |

| Spindle center | Morse No. 6 |

| Tailstock center | Morse No. 6 |

| Tailstock center load | 7000Kg |

| Tailstock sleeve stroke | 200mm |

| Surface roughness of fine turning outer circle | ≤Ra0.8μm |

| Fine turning outer circle roundness | ≤0.01 mm |

| Minimum unit of longitudinal and lateral movement | 0.001 mm |

| X-axis ball screw nominal diameter | Φ50 |

| Z-axis ball screw nominal diameter | Φ63 |

| Positioning accuracy A (X axis) | 0.012mm |

| Positioning accuracy A (Z axis) | 0.045mm |

| Repeat positioning accuracy R (X axis) | 0.007mm |

| Repeat positioning accuracy R (Z axis) | 0.01mm |

| Reverse difference B (X axis) | 0.006mm |

| Reverse difference B (Z axis) | 0.012mm |

| Installation size of machining tool | 300*45*45mm |

| Machine size (length*width*height) | 6250*1850*1800mm |

| Net weight of machine tool | 13000Kg |