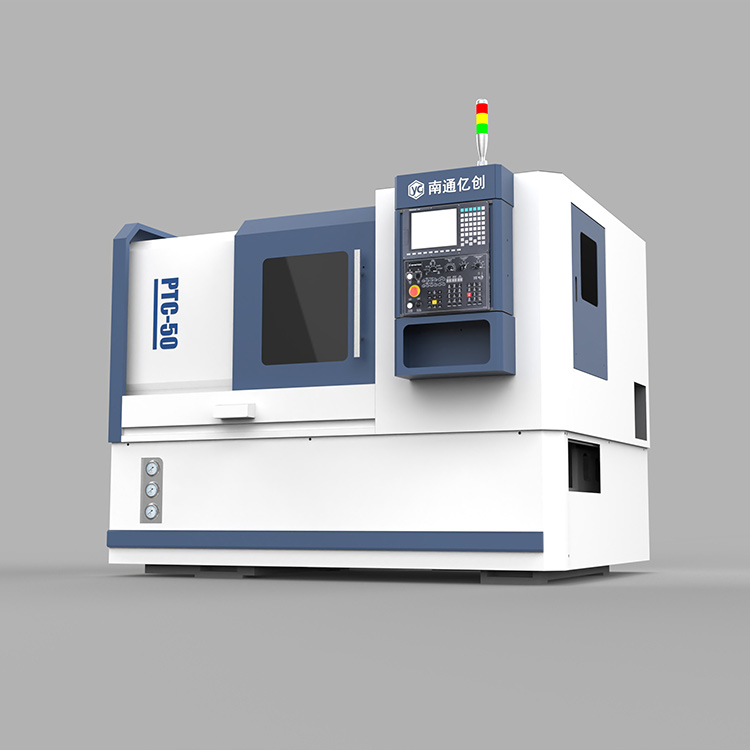

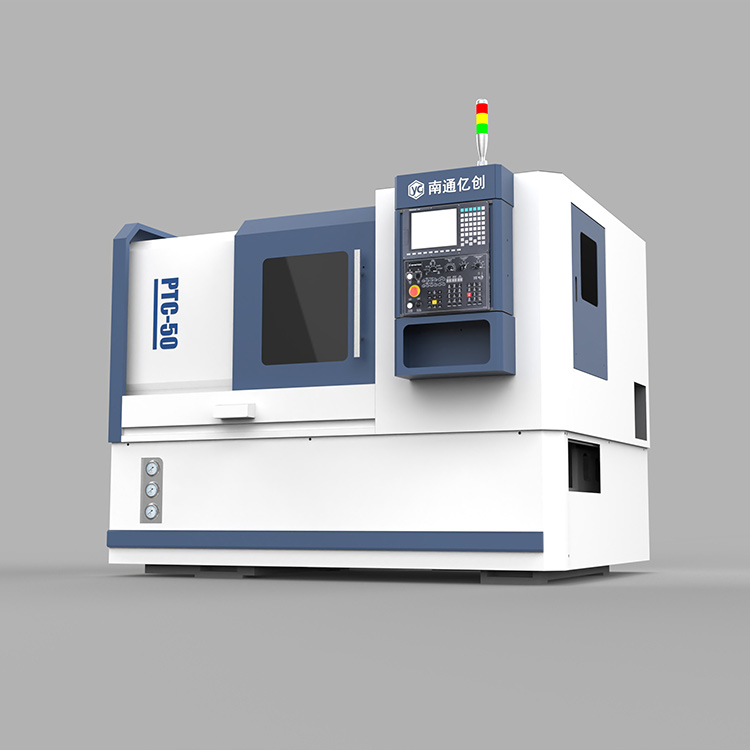

CNC vertical turning

Machining Center is a kind of CNC machine tool which integrates many machining capabilities such as turning, milling, drilling and tapping. Suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, can complete the shell, plate, casing and other parts processing.

● High precision: Through the precise control of the CNC system, the vertical turning machining center can achieve high precision machining to meet the processing needs of various complex parts. The positioning accuracy and repeated positioning accuracy are high, ensuring the stability and consistency of the workpiece.

● High efficiency: Vertical turning machining centers are usually equipped with multi-axis linkage system and automatic tool change system, which can achieve multi-sided machining at one time, greatly improving production efficiency. At the same time, it has a high degree of automation, reducing manual intervention and reducing production costs.

● Versatility: Vertical turning machining center can not only perform turning processing, but also milling, drilling, tapping and other processing operations, with strong versatility to meet different processing needs.

● Easy to operate: the structure of the vertical turning machining center is relatively simple, the floor area is small, the workpiece clamping and positioning are convenient, and the tool movement track is easy to observe, and the debugging program is convenient to check and measure.